A More Sustainable Solution for Cooling Towers, Boilers and Closed Loops.

RMC’s SolidGuard® Program is an innovative, effective alternative to traditional liquid water treatment that will help raise your bottom line. These highly concentrated products are packaged in 1 gallon containers and 6″ disc’s with companion dissolve units.

The goal of all boiler water programs is to maintain clean heat transfer surfaces. Beyond preventing insulating deposits, the program must protect system metals from the damaging effects of corrosion. Rochester Midland treatment options include chelant, all polymer, phosphate or carbonate programs. These available technologies used in conjunction with a wide selection of dispersants, oxygen scavengers and return line treatments will ensure safe, efficient boiler system operation.

- Scale Inhibitors

- Oxygen Scavengers

- Steam Line Treatment

- Fuel Treatment

- Antifoam

- Feed and Control Systems

- System Cleaners

- Closed Loop Treatment

Why Choose RMC?

RMC is a Market Leader in Providing Solid Products for Boiler Water Treatment!

RMC’s Solid products are used globally in commercial, institutional, and industrial systems to maintain equipment efficiency and reduce biohazards. The Solid technology provides improved health and safety to enhance sustainability.

Integrated Solutions

Why deal with two or more suppliers when you can partner with Rochester Midland? We have the unique ability to serve as a single source supplier for your specialty chemical requirements. From food plant sanitation to water treatment to environmentally safe cleaners, we bring a breadth of programs and application expertise that others cannot match. We look at your whole process to determine the best solution.

Benefits of Solids

The impact of a Solid Chemicals Treatment Program can be quantified in dollars by helping you save time (labor), shipping costs, and inventory costs.

Improved safety

- No liquids to spill – reduces the risk of slips and falls

- No powders to irritate

- No offensive odors

Increased savings

- Reduced weight equals reduced shipping costs

- No drum disposal costs

- Reduces scale deposits for better heat transfer saves on fuel usage

- Better corrosion control extends equipment life

Easy to transport

- Safer, lighter, easier to load and more ergonomic to reduce the risk of injury

- Less refills required: 50-90% fewer lbs. shipped

Sustainability

- Reduced weight equals reduced fuel usage and CO2 emissions

- Reduces water usage – use what you need when you need it

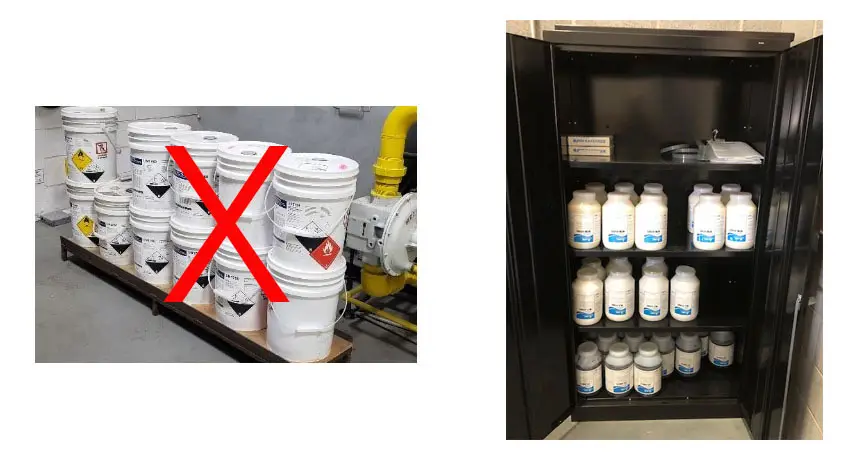

Maximized floor space

- Neater, cleaner, safer mechanical room

- Frees up floor space

- Compact size conserves space

LEED potential

- May be used to qualify for LEED® certification in innovation, design, solid waste management, sustainable purchasing

Before

After

To determine whether RMC’s programs can improve your operation, we will conduct a system survey. A representative from Rochester Midland Corporation will work with you to design a customized Solid Chemical Treatment Program to meet your specific needs. We offer the best in class solid chemical products, product dissolvers, pumps and control systems to help you maintain heat transfer efficiency in your boilers, cooling systems and closed loops.

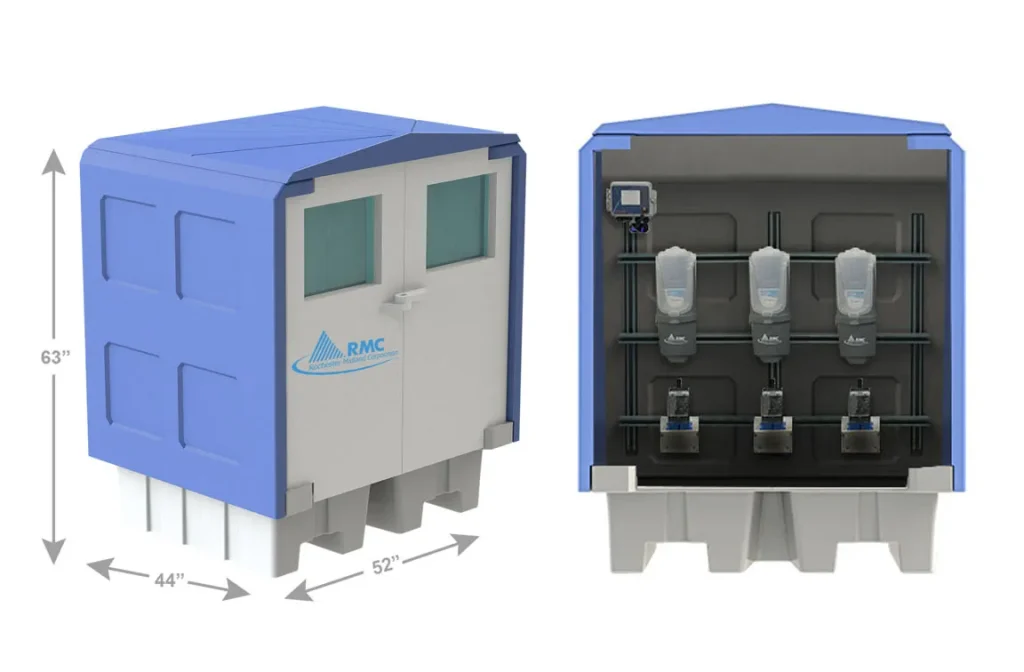

RMC Secure and Chemical Resistant Equipment Enclosure

The ultimate enclosure for your chemical feed pumps, dissolve units and monitoring controller.

- This enclosure provides secondary containment in a safe, secure, weatherproof, and lockable cabinet.

- Designed with extra room to handle not only chemical feed and monitoring equipment but will also accommodate piping manifolds, corrosion coupon racks, and a place for safe and secure product storage.

- This enclosure includes large swing-open doors with heavy-duty windows and liftable top hatch for easy equipment access at the time of installation and routine service.

- Highly chemical resistant in a wide range of chemical and corrosive environments. Made of durable UV Stabilized rotational molded polyethylene, never rusts or corrodes and designed to keep rain and moisture out.

Maximize Floor Space & Stop Hauling Pails

Keep floor space free from obstruction (unlike liquid-filled chemical pails, drums and bulk tank) optimize the square footage of mechanical rooms. Store cases of solid chemistry safely on shelves. No special containment is required.

Frequently Asked Questions

How are the Solids packaging disposed?

The packaging for RMC Solid products is fully recyclable. This includes the HDPE for the bottles, the fiberboard packaging for the product, the paper for the labels, and the wrapping for the discs.

Can the Ultra M Dissolve Units be installed outdoors?

Yes, RMC recommends that all chemical feed equipment be installed within a weatherproof enclosure. Your RMC representative will provide information regarding a suitable enclosure.

How difficult is this equipment to install?

Whether the equipment is panel-mounted in advance or installed loose in the field, the equipment essentially has 3 tie points for water/solution and 3 anchor points for the mounting bracket. All water/solution connections are easy to tie to, with tubing compression fittings for the inlet water and chemical solution outlet and hose barb for the overflow port. Once the units are installed, start-up and commissioning take minutes.

Are the Ultra-M dissolve units reliable?

The Ultra-M dissolve units were designed for increased reliability, quality and durability so our solid chemistry can be dissolved with confidence given any situation. The Ultra-M was built with the advantage of a non-electric mechanical level system and integrated flow control providing accurate chemical dosing for a variety of water treatment systems. All materials of construction are chemically compatible to the solid products in use.

Is the dissolving rate consistent when utilizing these solid products?

The products are designed to dissolve readily and rapidly to generate safe solutions. Water and ambient temperatures have a small impact on dissolution; these temperatures are often very consistent over shorter periods of time, making it easy to adjust feed rates as necessary. Most products can be field tested for solution strength, allowing for dialing in pump and feed settings during start-up and normal operation.

Can the switch from liquids to solids provide LEED credits?

Yes, CO2 reduction is a direct result of switching to solid chemistry. Assuming a 2,000-ton average load at 5 cycles of concentration, switching from liquids to solids reduce CO2 emissions by 56 tons annually. This can help achieve LEED credits.

Can you compare the amount of product between liquids and solids?

4 gallons of RMC Solid Treatment Chemicals are equivalent to a 55-gallon drum of liquid chemical treatment. Use what is needed, when itis needed, with no chance of liquid spill or component separation. No mixing equipment needed.

Is the solid product chemistry as effective as the liquid product chemistry?

Is this proven technology?

With over 20 years of application experience and a continual evolution of product and equipment technology, Solid Chemistry is proven to be a very effective and sustainable solution for cooling tower, boiler, and closed loop applications. With any technology, it takes professional water treaters to properly select, size, and implement solutions; RMC’s water and energy team is ready to.

How long have solid products been used in the industry?

Solid products have been used since the early days of water treatment, whether it be potatoes, tannins, etc. The Solid Chemistry form used by RMC has been in use for over 25 years.

How long has your company been utilizing solid chemistry?

RMC has had Solid Chemistry in their line for at least 10 years, with longer experience if you include folks who have used products prior to RMC’s incorporation of the technology.

Can solid product chemistry be used for cooling water treatment and boiler water treatment?

Yes, RMC Cooling water products for scale and corrosion control utilize trace chemistry for ease of testing and control. RMC is also market leader in boiler water treatment technology using solid products to treat boilers operating above 150 PSI.

How large of a system can the solid products be used on?

Solid product chemistry has been effectively used to treat cooling water systems in excess of 1000 tons. The development of the program which includes the applicable products and equipment will be provided by your RMC Technical Representative.