The Experts you Need when Productivity and Profitability Can't be Compromised.

When you work with an experienced RMC corrugated industry expert they not only know the importance of maximizing the life of your equipment, but they also know the impact clean, dry steam has on production.

Serving

200+ Corrugating Plants Nationwide

Experience

20 Years of Inustry Experience

Experts

RMC Corrugating Experts Find Simplified & Sustainable Solutions

The RMC corrugated technical specialist is connected to all levels within the corrugating plant, from the Plant Manager to the Boiler Operator. This includes EHS, production, and maintenance, we are an integral part of the team with many of the world’s most successful corrugating companies.

RMC understands the production process and can ensure equipment is adequately protected during non-production hours. Such as protecting off-line deaerators and high-pressure receivers, or ensuring the wastewater is within compliance during pit cleanings and starch kitchen dumps. It is RMC’s goal that the steam systems are always kept operating at peak efficiency, the life of Plant assets is maximized, and sustainable solutions are provided to keep plant personnel safe.

They Know...

- How to train operations personnel on the importance of water treatment and the impact high-quality steam has on the corrugating process

- How to minimize carry-over and wet steam when it comes to troubleshooting industrial boilers

- How to help increase production

- How to reduce utility costs

At a large Corrugating Box plan, RMC was able to save over $43,000 per year in utility expenses by increasing the operating efficiency of the boiler.

They are Experienced Wastewater Consultants Who...

- Simplify the treatment process

- Improve safety through minimizing the risks associated with handling hazardous liquid chemicals

- Maintain environmental regulations

- Provide ongoing training to operations personnel

- Understand the entire corrugating process, not just the boiler and wastewater treatment requirements

- Are proactive by continuing to look for opportunities to improve your overall process

- Assist in monitoring boiler operations, checking the deaerator and high-pressure receiver temperature and pressure

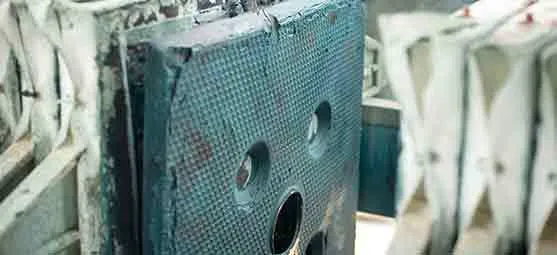

- Actively look at the steam showers and the impact that the steam has on the corrugating process

- Assist with improving the results of the starch process

- Provide the equipment, chemical treatment products, and application technology to

- Help you achieve your goals

- Lower energy and water costs

- Increase profit

- Meet environmental discharge regulations

They Have Close Relationships with Steam System Suppliers that Specialize in the Corrugating Industry Who...

- Work together to help prevent and solve problems

- Work together when a new DA, HPR or Boiler is installed so that the treatment process is done correctly from day one

- Provide state of the art chemical feed and monitoring equipment that meets the needs of your operation

Product Solution Resources

Meet Our Corrugated Industry Experts

Vince

35 Years

Karen

30 Years

Ali

15 Years

Bill

33 Years

Brad

10 Years

Micheal

38 Years

Johnathan

8 Years

Shane

25 Years

Rance

(Canada) – 30 Years