Since the inception of COVID-19, many manufacturers still find themselves in uncharted territory on how to best mitigate their risk while still trying to conduct business as usual. Although there is no evidence that the virus is transmitted through food or packaging materials, it is still critical to establish and implement a control plan centered around common sense while utilizing science-based interventions.

Background

Numerous reports in recent weeks show an increased number of meat and poultry processors impacted by COVID-19 outbreaks, resulting in many to shutter operations due to concern with employees contracting the virus. Some of the highlights include:

- JBS (Beef)-Greeley, CO ceased operations in mid-April, but has since reopened (245 Cases)

- Tyson Foods (Pork)- Logansport, IN ceased operations on April 25th; scheduled to reopen week of May 4th (Approximately 900 cases)

- Tyson Foods (Beef)- Joslin IL (92 Cases)

- Cargill (Turkey)- Duplin NC- (58 Cases)

- JBS (Pork)- Worthington, MN ceased operations on April 20th (Approximately 500 cases)

The Basics

Common sense goes a long way! This direct approach is basic and simple, but often times overlooked. Cover your mouth when you sneeze or cough and wash your hands with soap and hot water for at least 20 seconds followed by the use of an alcohol-based sanitizer. Outer garments and gloves should be changed immediately if contaminated or used to contain and prevent discharge from the mouth or nasal area. All illnesses should be reported to management immediately. A written policy should be in place and include a return-to-work policy including the steps taken to minimize exposure to product as well as other employees.

Masks

Face masks and other facial equipment continue to be adopted and implemented now more than ever before. It is, however, important to be realistic about their purpose as well as recognize their limitations. The cold, humid environment found in meat and poultry facilities is ideal for SARS-CoV-2 to proliferate, resulting in most manufacturers to implement the wearing of facial masks. It is important to consider the type of mask being used and its effectiveness. Vented masks similar to the ones used in surgery are more effective than disposable alternatives and can be cleaned/reused. N95 and N99 masks, which use GAC cartridges, aid in drying out the air, which further reduces the chance for the virus to survive. Additionally, they offer easier respiration which is important considering the amount of physical labor required in meat processing.

Social Distancing

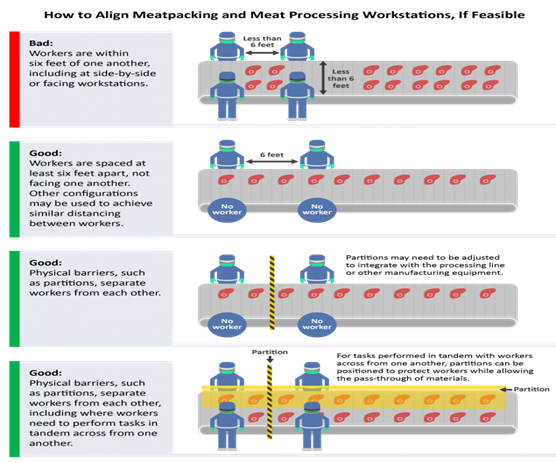

You have likely already seen it in place including limiting the amount of people within an occupied space, or perhaps with visual indicators on the floor to help illustrate keeping sufficient distance from others around you. This can be more of a challenge in production facilities due to the number of people. The following practices are both practical and easily implemented:

- Increase distance of in-line work areas and break rooms per CDC’s recommendation of 6 feet between individuals. Staggering workstations for workers directly across from one another can also help to minimize face-to-face contact. Physical barriers can also be installed in maintaining adequate distance. This is a simple method that doesn’t require building physical barriers, but continuous monitoring is required for maximum effectiveness. It may be necessary to slow the process down in order to accommodate fewer personnel.

- Stagger work shifts and breaks to minimize the number of employees in common areas such as parking lots, entrance/exit points, changing areas, breakrooms and restrooms.

- Restrict non-essential physical contact such as handshaking and other physical contact.

Raising the Sanitation Bar

Since the inception of the outbreak, there has been a raised awareness on the importance of sanitation, including additional cleaning and sanitizing activities. As a result, chemical demand has increased rapidly resulting in challenges to chemical suppliers to keep up with demand. Caution and discretion must be used when choosing these chemicals and should take into account:

- Is it approved for use in food manufacturing facilities? Where can it be used (common areas such as break rooms and bathrooms), in and around food production including food-contact surfaces and at what concentrations?

- Is it registered for use against viruses or included in EPA’s List N requirements for Products with Emerging Viral Pathogens AND Human Coronavirus claims for use against SARS-CoV-2?

- What application is it approved for (direct applications, fogging, etc.)?

A few of the RMC sanitizer options for use in non-food production areas (breakroom and restroom areas, etc.) include CP-64, Quat Plus TB, and Enviro Care Neutral Disinfectant. F-29, a quat-based sanitizer, is a great all-around option and can be used throughout the facility including food-contact surfaces, contact points, and as a fogging application, including production and non-production areas (offices, hallways, etc.). Additional information can be found in the link below from Charles Giambrone, VP of Technical Services for RMC.

Additional Considerations

Most companies have added requirements for monitoring the body temperature of their employees as part of a proactive approach to help slow the spread of the virus. Elevated temperatures of 99.5°F and above have been associated with the virus, which usually require the employee to seek medical attention and not return to work until cleared by a physician.

As we continue to manage through these challenging times in the weeks and months ahead, it is important to remain optimistic and open-minded. We will get past this in due time, but should remember to take it one day at a time.

Works Cited

WHO 2020- “COVID-19 and Food Safety: Guidance for Food Businesses” World Health Organization. https://www.who.int/publications-detail/covid-19-and-food-safety-guidance-for-food-businesses

Ryan McCarthy, 2020- “CDC, OSHA Announce Interim Guidelines for Meat Plants” Meat & Poultry. https://www.meatpoultry.com/articles/23025-cdc-osha-announce-interim-guidelines-for-meat-plants

Meatingplace Editors, 2020- “COVID Update: Tyson, Cargill, Butterball” meatingplace.com. https://www.meatingplace.com/Industry/News/Details/91844

Tom Johnston, 2020- “JBS Sees COVID-19 Cases Surge in Colorado; Tyson to Reopen Indiana Pork Plant” meatingplace.com. https://www.meatingplace.com/Industry/News/Details/91817

Tom Johnston, 2020- “JBS Reopens Minnesota Pork Plant, But Only to Euthanize Pigs” meatingplace.com. https://www.meatingplace.com/Industry/News/Details/91824

CDC 2020- “Meat and Poultry Processing Workers and Employers: Interim Guidance from CDC and the Occupational Safety and Health Administration (OSHA)” Centers For Disease Control and Prevention. https://www.cdc.gov/coronavirus/2019-ncov/community/organizations/meat-poultry-processing-workers-employers.html