The proper preparation and execution of a food processing fryer requires a thorough comprehension of the sanitation principles utilized for all system components. Implementation of appropriate chemistries in concert with the design components of the system are key to creating a functional SSOP. These same principles are also applicable to all post-fryer processing equipment for product cross-contamination and contact issues that can and do occur.

Sanitation practices must incorporate the SSTARTEC principles:

- Soils

- Surfaces

- Temperatures (surfaces, rooms, chemicals)

- Agitation

- Rinses

- Time

- Environment

- Chemicals

- Concentration

Fryers have a composite of fats, proteins, and carbohydrates that create carbonized residues. These soils are dependent upon product composition and the prescribed scheduled sanitation frequencies. Fryers used in French fry production involve a high carbohydrate, high fat soil matrix containing a large volume blend of unsaturated and saturated oils. They are typically cleaned weekly, but in some instances may be 2-3 weeks before a deep cleaning occurs. In contrast, a cake donut fryer is typically deep cleaned daily due to the smaller volumes of fry oil. In between are potato/vegetable chips as well as high protein snack foods. Products that are coated prior to frying can range from a light coating to a thick batter and can create other issues with carbonized residues.

A variety of cleaning modalities are employed due to the nature and complexity of the process equipment design. These include extensive preparation by scraping excess carbonized creosote type soil residues from all components after the fryer oil has been drained, strained, and retained in a holding tank. The thoroughness of these preparation steps prior to completing the boil out process will make or break the effectiveness of the entire process.

Foam cleaning occurs during the entire process in concert with high pressure rinsing. CIP circuits are used for major components as well as a COP tank for critical tear down parts. The cleaning chemistry pH range will vary from highly caustic to acidic neutralization of the caustic to re-establish the fryer oil’s moderate acidic pH. In highly carbonized, high residue cleaning, the utilization of an acidic peroxide to potentiate the caustic boil out cleaner’s performance and concentration are highly effective and recommended.

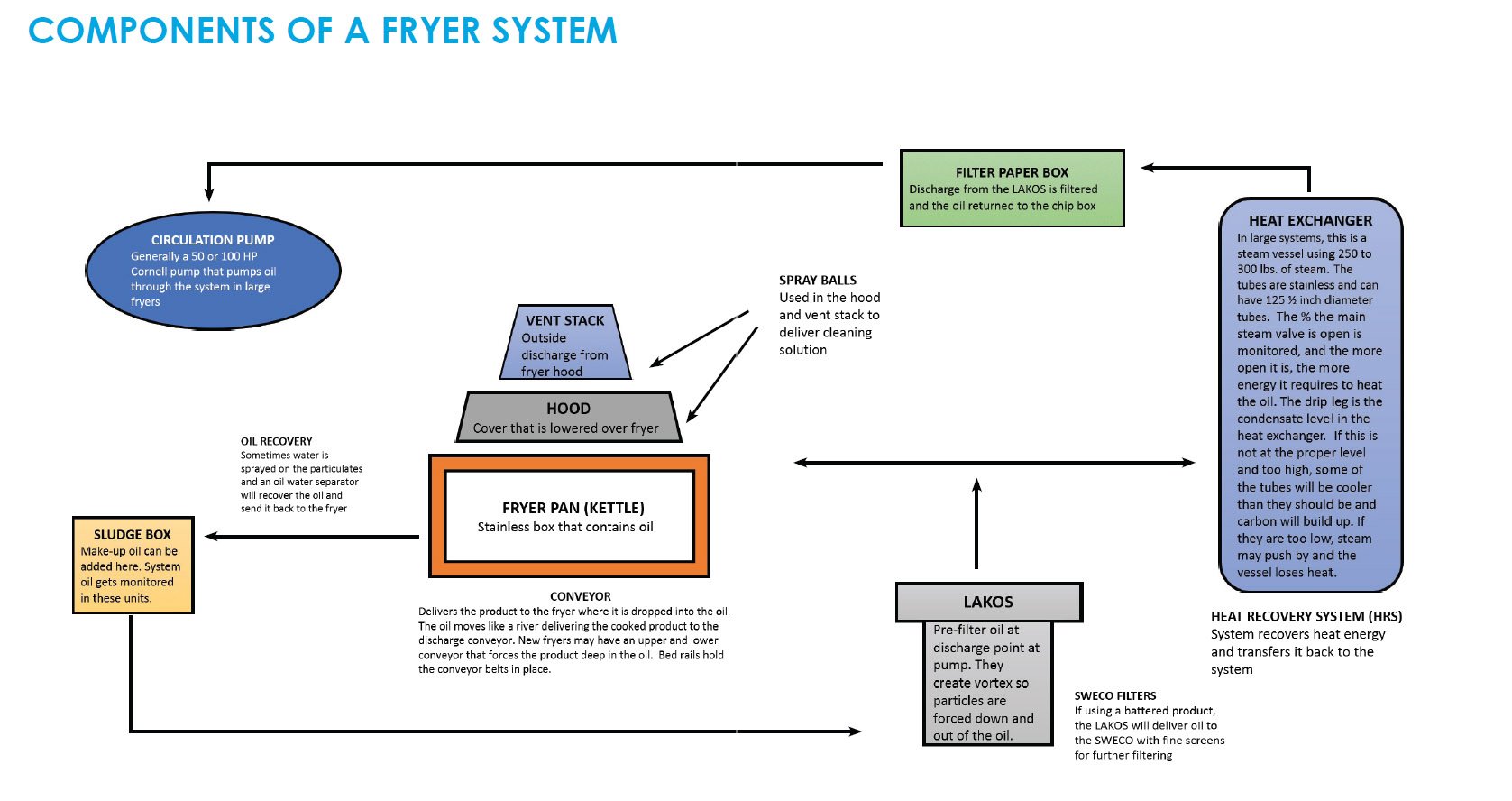

The cleaning process must be approached based upon the system’s components and the proper sequence of the entire cleaning process. The key components include:

- Fryer Bed/Pan/Kettle- A vessel that holds the oil. A conveyor is often used to transport the product through the frying process.

- Hood- Covers the vessel and controls exhaust fumes.

- Vent Stack- Exhausts fumes to exterior.

- Sludge/ Chip Box- Adds make-up oil to system and is linked to the oil recovery system.

- Lakos Unit- Transfers oil from the sludge box and pre-filters via vortex using Sweco filters; feeds fryer kettle & heat exchanger with filtered oil.

- Heat Exchanger- Utilizes steam to heat the oil using a series of stainless steel tubes.

- Filter Paper Box- Removes discharge from Lakos and returns the oil to sludge/chip box.

Efficiencies are measured by maintaining the fryer's temperature range during production. The proper time and concentration of cleaning these components, particularly the fryer bed and conveyor, heat exchanger, and tubes is critical. An effective boil out should take no longer than 3 hours to complete and does not require filling the fryer bed to maximum volume with diluted caustic cleaner.

“Super Charging” the heat exchanger and tubes is strongly recommended. All CIP valves should be closed to all stacks using a low water volume. The key CIP components include the vent stacks, sludge/chip box, fryer circulation pumps, and filter box stacks. After an initial hour long boil out, the water level is raised and all CIP valves to all CIP components is performed. The same process should be completed for the critical rinse cycle. If the CIP design or performance on these components is incomplete, particularly the vent, it can result in costly fires due to a buildup of creosote residues.

The boil out should include the utilization of caustic gel cleaners on exterior components that also constitute a portion of the actual caustic cleaner use concentration. The critical acid neutralization step is needed for achieving the fryer oil pH range.

|

Before |

After |

An additional critical sanitation parameter deals with all post-fryer components, including cooling tunnels/cooling spirals. Products such as potato and corn chips, as well as IQF snack foods, are cooled to ambient temperature prior to packaging.

Any food spoilage or pathogenic microbes introduced as cross-contamination during the post-lethality stage can have dire food quality and food safety consequences, thus mandating a detailed analysis of the hygienic design issues and flaws of all post-fryer equipment.