The disposal of wastewater in the corrugating industry can be challenging. The lack of suspended solids may make it difficult to solidify the waste for disposal. The treatment plan typically requires numerous liquid chemicals to adjust the pH, remove inks, metals, and other materials that will provide a wastewater stream clean enough to discharge and dry solid cakes that can be transported for disposal. Rochester Midland Corporation has a sustainable solution for these challenges.

RMC has developed clay-polymer blends in four different products to solve the problems associated with waste disposal in the corrugating industry.

Clays are typically used as a “coagulant aid” to help increase the solids of water and create a pin floc when there may not be enough particles in the wastewater stream. In many cases, this helps to remove low levels of contaminants such as metals. Another way clay works to remove chemical wastes in the water is by a chemical process known as “adsorption”. Clay particles are negatively charged and attract positively charged particles to the surface of the clay polymer.

A clay-polymer blend also contains a polymer or what we typically refer to as a flocculant. A flocculant uses the process known as bridging to connect the smaller pin flocs together into larger aggregate particles. These larger, heavier particles settle quickly – separating the liquid from the solids. Since wastewater stream particles may have varying degrees of positive and negative charges, there are four different polymer blends to handle the different types of waste streams.

The unique property of the RMC clay-polymer blends is that the coagulant and flocculant/polymer are blended into one product. This blend of clay coagulant and polymer flocculant is all that is needed to clarify the water. We have had good success with producing clean water for discharge and a much dryer sludge cake in the filter press or in a rotary drum filter prior to disposal. Dryer sludge will reduce hauling cost and reduce the operation time of the filter itself as well as reduce the filter cleaning time.

For example, particularly in the corrugating industry, removing ink from water is a challenge and we attribute our success with ink removal to the inclusion of clay in these RMC products.

Formulating these products with a dry version of a coagulant provides several benefits in comparison to the liquid version that most corrugators use in totes. Manufacturing these products into a concentrated dry formula reduces the freight cost, eliminates handling of totes and hazardous acidic chemistry. It also reduces the footprint for storage. Our unique products contain an all-in-one sustainable wastewater solution designed specifically for corrugators. RMC’s unique clay-polymer products are the solid choice for your water treatment needs; ease of use, cost savings, smaller footprint, improved results, and a wastewater program that is better for the environment.

SUCCESSFUL RMC CASE STUDY:

Issues Prior to Treatment:

- 10 to 12-hour press times.

- Jar tests did not correlate to batch treatment.

- Had to occasionally bypass treatment due to volume.

- Floc did not press well – no solid cakes.

- Cloudy, dirty effluent.

- No pH probe.

RMC implemented the clay-polymer program with the MF-3390G product. The result was as follows:

- 3.5-hour press times for solid cakes.

- 0.5 grams in jar tests exactly corresponded to the dosage in the batch.

- Zero bypass of treatment since MF-3390G was started.

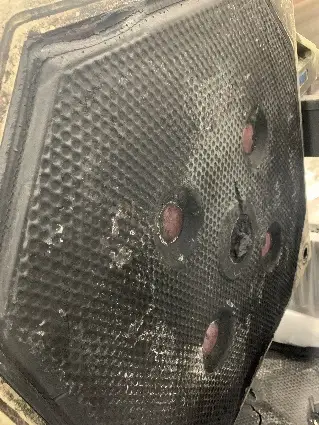

- Perfect presses with dry filter cakes.

- Clean water discharged from the plant.

- No pH adjustment necessary.

Pictures of the dry filter cakes are shown below.

The benefits of using the clay-polymer chemistry versus the liquid chemistry are:

- An average of 30 -68% cost reduction per year.

- One non-hazardous product versus liquid chemicals which may be hazardous.

- Hauling cost reduction in sludge weight/volume.

- Elimination of multiple liquid chemical pumps.

- Elimination of storage, handling, and disposal costs of liquid drums and totes.

- No capital costs to convert to RMC product technology.

- Operating Staff will like the simplicity of the single product.

- Elimination of the use of Diatomaceous Earth for pre-coating the filter presses.

- A consistent, dry filter cake is obtained, meeting the landfill requirement for non-hazardous material.

- Improved settling time with the sludge after treatment. This allows for quicker decanting of the water, increasing the hydraulics of the system.